INNOVATIVE CONSTRUCTION TECHNIQUES

DCW Squared is proud to be able to offer you not only expert industry leading consulting and management services for traditional building systems such as balloon/stick build wood frame, CMU Block, cast in place concrete and steel frame, but also for more non-conventional methods detailed below. We hope you contact us to discuss the options that will most precisely fit your needs and objectives. We will also be able to advise you which method might be most suitable to any LEED certification goals you might want to achieve.

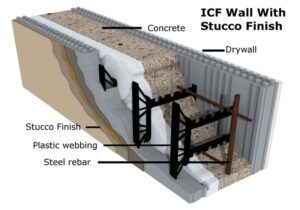

Insulated Concrete Form (ICF) System

Insulating concrete form (ICF) construction using Expandable Polystyrene (EPS) foam (Styropor®) block system was first patented in 1966 and has been in use ever since. Today, these blocks are made today from a multitude of materials, many of which are from recycled and or sustainable sources. These blocks create the formwork for the steel reinforced concrete walls providing the building its incredibly durable structure. The blocks will stay in place as a permanent substrate on the exterior and interior of a structure. It is used for roofing, flooring, and walls in the construction industry. The best way to think about its use is to compare each block to a Lego brick that you can eventually piece together to create the structure that you want.

Because there are stringent energy-efficiency rules to follow today, more contractors are turning to ICF construction to create buildings that meet the current codes. This structure is naturally more resistant to natural disasters as well, and it is useful in applications where there is a need for frost-

protected shallow foundations. In tropical areas the resulting buildings stay cooler due to the high thermal factors of the resulting walls. A welcome side effect of this wall system is the near elimination of “sweating” of interior walls reducing the occurrence of mold and mildew. Finally, as mentioned above, the house structure is virtually Hurricane proof. ICF systems are suitable for all climates and seismic zones.

Let DCW Squared, LLC help you decide if an ICF system is the right solution for you!

Tilt-Up Concrete Panel Construction

Tilt-up, tilt-slab or tilt-wall is a type of building and construction technique using concrete panels formed horizontally on a concrete slab or other well prepared flat surface. Though it is a cost-effective technique with a shorter completion time, it is most suitable to large-scale projects such as in commercial and industrial applications. Still, the technique has been successfully used for high density residential projects like Apartments and Condominiums as well. At one time Tilt-up construction had received a poor reputation regarding performance in earthquakes. With today’s engineering standards this has been overcome and the system can be designed for all seismic zones.

Though it is a cost-effective technique with a shorter completion time, it is most suitable to large-scale projects such as in commercial and industrial applications. Still, the technique has been successfully used for high density residential projects like Apartments and Condominiums as well. At one time Tilt-up construction had received a poor reputation regarding performance in earthquakes. With today’s engineering standards this has been overcome and the system can be designed for all seismic zones.

Tilt-up construction is a common method of construction throughout North America, several Caribbean nations, Australia, and New Zealand. It is not significantly used in Europe or the northern two thirds of Asia. It is gaining popularity in southern Asia, the Middle East, parts of Africa, Central and South America.

A DCW Squared, LLC specialty consultant will be happy give you more information on Tilt-Up Concrete Panel Constructions for your application.

Precast Concrete Systems

While similar to Tilt-Up construction, Precast Concrete Systems differ in many ways and are suited for all types of construction. From single family homes, to high rises, and commercial and industrial buildings. Most are familiar with precast concrete for cisterns, septic tanks and utility drainage systems, but over the last 50 years, more and more building components have been produced in controlled environments with strict quality control supervision. Panels can be produced in a wide variety shapes, colors, textures, and sizes and are usually only limited by the requirement to enable shipping. The panels can also be produced with conduit and piping embedded.

The use of precast concrete systems is most advantageous in areas where environmental factors do not allow for or that make the placement of concrete extremely difficult. Your schedule might also be a deciding factor since the overall construction time of a precast structure is usually 25% faster than other methods.

allow for or that make the placement of concrete extremely difficult. Your schedule might also be a deciding factor since the overall construction time of a precast structure is usually 25% faster than other methods.

Precast panels are often used in conjunction with Steel or concrete frame designs for interior and exterior infill walls. This is a quick and economic way to create larger buildings.

DCW Squared, LLC’s professionals will be able to advise you on the benefits of Precast Concrete Systems for your project.

Prefab Panel Construction Systems / Custom Modular Wall Construction

People are just now realizing their true benefits of Prefab Panel Construction Systems / Custom Modular Wall Construction. This system simply includes the process of making wall sections in a factory instead of out at the construction site. By doing this we reduce waste, miscuts and miscalculations, control costs and insure a consistently high-quality product. By doing this we reduce waste, miscuts and miscalculations, control costs and insure a consistently high-quality product. These panels can be constructed with a wide variety of building materials – and not just wood stud – therefore the system lends itself to adaptation to your need. Buildings can be designed as permanent or semi-permanent based on the clients intended use. The System is designed to mass production, which is ideal for housing

By doing this we reduce waste, miscuts and miscalculations, control costs and insure a consistently high-quality product. These panels can be constructed with a wide variety of building materials – and not just wood stud – therefore the system lends itself to adaptation to your need. Buildings can be designed as permanent or semi-permanent based on the clients intended use. The System is designed to mass production, which is ideal for housing developments when a limited number of home models are offered; for Long- and short-term worker camps; and office complexes. They are also perfectly suited for school and hospital expansion projects and many others.

developments when a limited number of home models are offered; for Long- and short-term worker camps; and office complexes. They are also perfectly suited for school and hospital expansion projects and many others.

For more information and to see if Prefab Panel Construction Systems / Custom Modular Wall Construction is the answer to your needs, contact DCW Squared, LLC.

Other Construction Methods

There are a vast number of other building systems, and DCW Squared, LLC’s professionals can help you with your decision. Let us know if you are interested in some of the more avant-garde building methods available today. Be advised that the use of alternative building systems might be restricted or not allowed by code in your area.

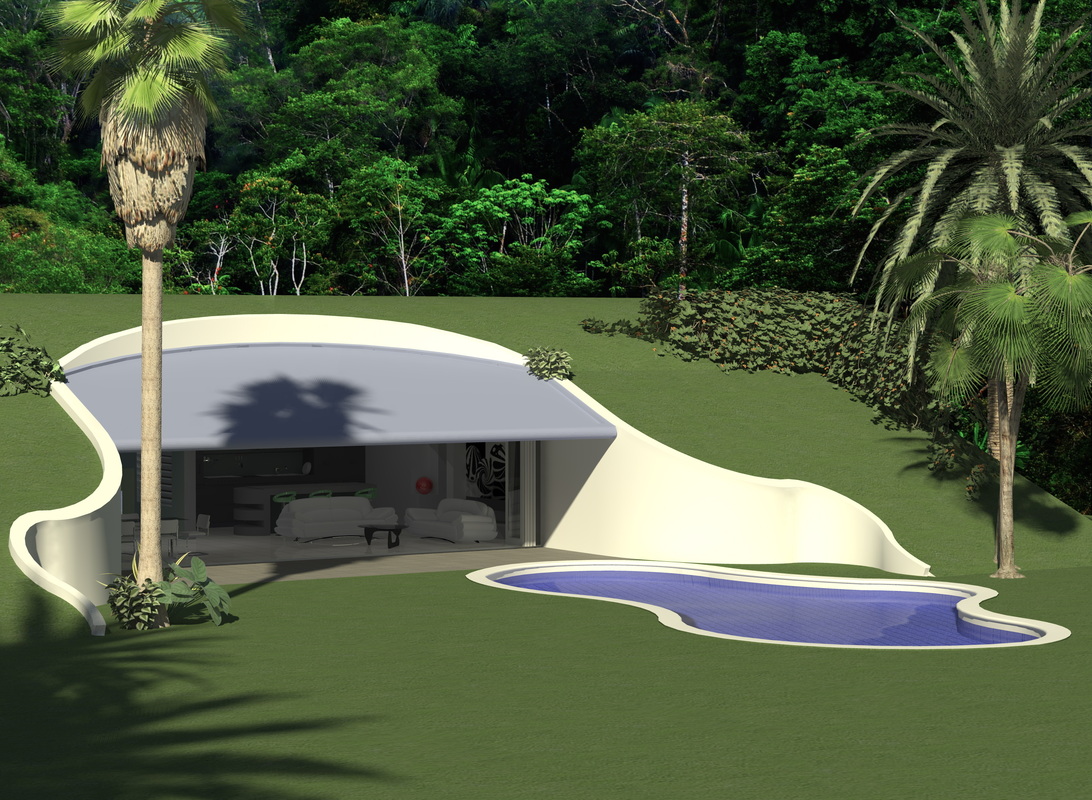

Earth Berm Construction / Earth Shelter:

An earth shelter is a structure covered with earth (soil) against the walls, on the roof - or that is entirely buried underground. Earth acts as thermal mass, making it easier to maintain a steady indoor air temperature and therefore reduces energy costs for heating or cooling. Earth sheltering became relatively popular after the mid-1970s, especially among environmentalists. However, the practice has been around for nearly as long as humans have been constructing their own shelters.

Post and Beam Construction:

Simple and transparent while being an elegant expression of craft, post and beam construction has a lot to offer. It is a simple straight forward  design concept, that is complex in execution and beautiful to behold, as the resulting structure molds space to form rhythms and patterns, while defining rooms. It is also a very durable method of construction.

design concept, that is complex in execution and beautiful to behold, as the resulting structure molds space to form rhythms and patterns, while defining rooms. It is also a very durable method of construction.

The simplicity of the basic structure gives rise to opportunities to explore how connections are made. These connections, whether mortise and tenon or bolted plates of steel, are inherently mechanical. As such, they are wonderful design opportunities that allow you express your own particular aesthetic, be it all sleek and modern or more rustic and handmade.

Haybale Construction:

From the first green built Post Office in the United States in Corrales NM. to a weekend cottage in Pembrokshire in Wales, United Kingdom, or a retirement home in Independence, Virginia;

Haybale construction seems to be everywhere. Not surprising, if you want to use an environmentally friendly renewable source building material with walls surpassing R-50 insulation values, you can’t get much better then haybale construction. The material lends itself to very organic almost romantic shapes but can also work for a minimalist’s modern design dream. Your imagination for your project is the limit.